Fairmont, MN radio station KSUM/KFMC interviewed Matthew Baumgartner of BEI at the MN Pork Congress. Listen to the interview here:

Fairmont, MN radio station KSUM/KFMC interviewed Matthew Baumgartner of BEI at the MN Pork Congress. Listen to the interview here:

Minnesota swine veterinarian Gil Patterson looks for three things when he walks into a hog barn: feed, water and air quality.

“You’ve got to have those things right before you can really dig into other issues. If there is a dusty, poorly ventilated environment, then it is uncomfortable for both pigs and farm employees, often leading to reduced growth and poorer-quality chores,” says the St. Peter, MN, Swine Vet Center clinician.

Continue reading:

EPI Air is on the cover of the November issue of National Hog Farmer! New research by Dr. Gil Patterson (Swine Vet Clinic) and U of M Researchers points to EPI Air having an impact on reducing PRRS. Read all about it.

It just makes sense…clean air is better!

Here is what Dr. Gil Patterson of Swine Vet Center has to say about EPI Air and PRRS. Dr. Patterson has conducted research evaluating EPI Air’s effect on the PRRS virus:

“The PRRS virus is one of the most challenging diseases that affect swine. It is especially difficult to contain and control because of its ability to travel through the air. Recent research has demonstrated that EPI air helps reduce the quantity of aerosolized PRRS virus both within and outside of commercial swine barns. This helps to improve the health and performance of PRRS-challenged pigs, and reduces the threat of transmission to neighboring herds.”

View this intereactive map to see where we have installed EPI systems. There may be one near you!

https://mapsengine.google.com/map/edit?hl=en&mid=zjini0oGLs-E.kDhra5EGkB44

Thank you to everyone who stopped to see us at the World Pork Expo. It’s always fun to see old friends and make new ones. The winners of our $100 giveaway are:

Corey Redfield

Irv Sether

Brad Greenway

Mark Bruening

Yon Kohlnhofer

Feedstuffs, March 25, 2013

Feedstuffs, March 25, 2013By Krissa Williams, Industry Insider

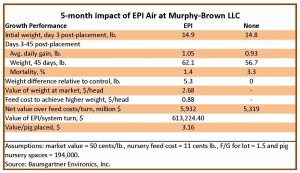

By Murphy-Brown LLC, North America’s largest hog producer, has generated an additional $1.896 million in five months at its commercial nurseries in Milford, Utah, thanks to a new air filtration system. Based on 194,000 nursery spaces, an enhanced environment created by EPI (electrostatic particle ionization) Air is adding $3.16 per pig placed (Table), according to the company. EPI Air is the patented product of Baumgartner Environics Inc. (BEI) of Olivia, Minn. The technology generates electrically charged ions that clear the air of dust and other harmful emissions such as ammonia and hydrogen sulfide. In February, Murphy-Brown released system-wide pig performance data comparing pre-EPI versus post-EPI technology and involved 600,000 nursery pigs. With a fi ve-week nursery period, the net value per turnover feed cost was $5.318 million for the pre-EPI environment and $5.932 million for the post-EPI regime. Bob Coffelt, business development director at Murphy-Brown, said the company is pleased with the results and noted that they were better than projected from initial trial runs. He also believes the company will be installing the technology into all of its grower/fi nishing facilities as well. Murphy-Brown markets 17 million pigs annually. “We’re tremendously excited about these results and thankful that Murphy-Brown continues to be visionary in this entire cleaner air issue,” said Matthew Baumgartner, general manager and head of development of the EPI technology for BEI. “They recognize the ongoing value of EPI Air and are now reaping significant economic benefi ts of the technology.” Next on the horizon is an improved version of the original EPI technology that positions the corona points (discharge points) 50 in. above the fl oor level and concentrates cleaner air in the “pig breathing zone.” The new generation also reduces dust accumulation on the ceiling and lowers capital costs. “This will likely increase the overall efficiency because you are placing this blanket of ions closer to the pigs. Plus, inside walls and ceilings may stay cleaner because the dust collection process will be at a lower level. Making ‘nuisance dust’ less prevalent is a good thing for employees,” Coffelt said.

The original system provides ionization for about 6,000 sq. ft. per unit; the new generation system will handle 15,000 sq. ft. of fl oor space per unit. Baumgartner said his firm will be marketing turnkey packages, meaning his recommended crew will be doing the installation. For a 60 ft. x 100 ft. nursery structure, the installation time would be about eight hours. Operating costs are comparable to the cost of running a 100-watt bulb for 24 hours, he said. The air system has proven to improve the environment and increase profits, but it may also reduce the threat of porcine reproductive and respiratory syndrome (PRRS), which continues to be the most costly disease plaguing the swine industry. Current estimates indicate that PRRS costs swine producers $650 million per year. “It continues to be the disease that shakes the industry,” according to Coffelt.

Is it possible that cleaner air may lessen the PRRS threat? While Coffelt’s theory has not been confirmed, Dr. Montserrat Torremorell, Leman chair in swine health and productivity at the University of Minnesota, is currently researching this very issue for EPI Air and non-EPI Air environments. Additional PRRS research using EPI Air is also being conducted by Dr. Qiang Zhang at the University of Manitoba. “It will be most interesting to see if these tests do reduce the overall level of PRRS virus density. Logic suggests that as you move the dust particles out of the air, you are removing bacteria also, so perhaps this might be a positive result, but I certainly wouldn’t make that claim at this time,” Coffelt said.

http://fdsmagissues.feedstuffs.com/fds/PastIssues/FDS8512/fds14_8512.pdf

This is a video of a newly installed EPI Air system in a swine nursery. This EPI system concentrates cleaner air in the pig breathing zone, and reduces dust build up on the ceiling and lights. The system only weighs approximately 0.4lbs/foot.