Tag: EPI Air

Swine Quarantine Combines EPI Air and Filtration

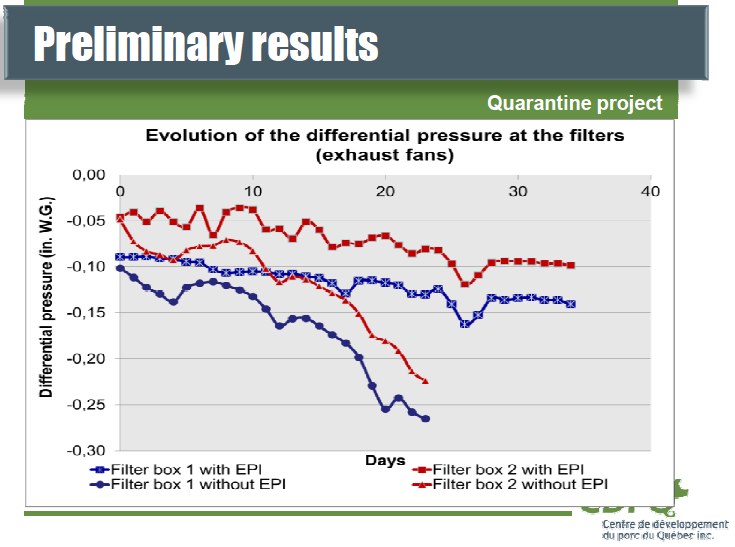

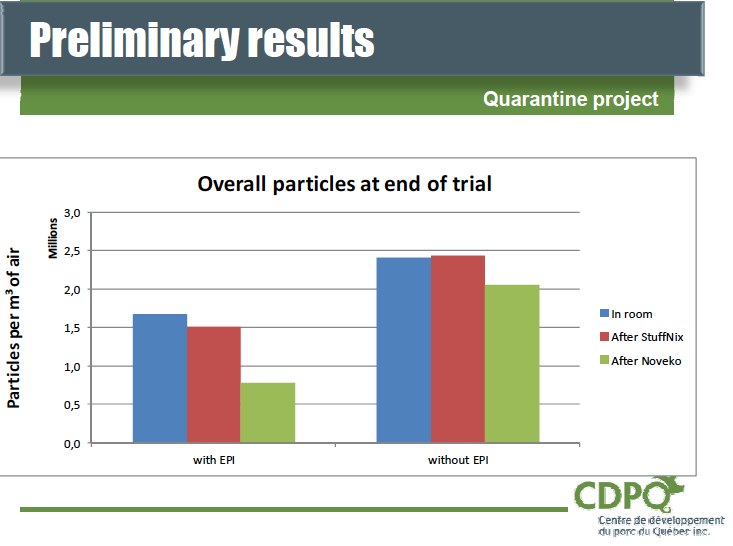

A recent Quarantine Project in Canada is studying new ways that a bio-containment system could be adapted for a swine barn. The preliminary results of the study were presented by Francis Pouliot, Eng M.B.A of the CDPQ, at the Annual Canadian Swine Health Forum. The objective of the project was to quarantine infected gilts and prevent the spread of viruses into the atmosphere. In addition to making sure the viruses stay inside the quarantine room, they also studied how a new ventilation system could reduce the rate of clogging and maintenance of the filters, cutting cost to an affordable rate. Clogging and maintenance of the filters is the main problem with the concept of installing filtration equipment over the exhaust fan of a swine quarantine building. This innovative quarantine project used a combination of EPI Air® and filtration to achieve promising results (Read the project summary here).

One of the key challenges of this quarantine system is reducing the clogging rate of the filters at the exhaust fans, in an affordable, maintenance-reducing way. This is where the EPI (Electrostatic Particulate Ionization) Air System is used.

The Ionization System:

- The EPI Air System is used inside the building to reduce the concentration of dust in the ambient air.

- EPI Air’s effect significantly reduced the clogging rate and maintenance needs of filters.

The Filtration System:

- Cyclonic pre-filters and antimicrobial filters are installed in front of exhaust fans to prevent viruses from escaping quarantine. Additional filters are installed over air inlets to prevent PRRS virus or other airborne diseases from entering the quarantine room.

- The efficiency of the cyclonic pre-filters and the antimicrobial filters at blocking dust and microbial load are measured with and without using EPI Air.

The preliminary results of the quarantine project are very promising. Take a look at the charts below from Francis Pouliot’s CDPQ Presentation, to to see how EPI Air made a significant difference reducing the overall dust concentration in the room and how EPI Air extended the useful life of the filter box. We look forward to seeing the final results of this study.

A portion of this project funding was provided by the sector councils of Quebec, Ontario, Manitoba, and Saskatchewan who administer the Canadian Agricultural Adaption Program (CAAP) for Agriculture and Agri-Food Canada.

Read about how Manitoba, Canada is improving the air quality in swine barns.

Reducing Secondary Complications in PRRS Infected Pigs

There is no doubt that the PRRS virus is a vital health concern for swine producers. PRRS (porcine reproductive and respiratory syndrome) is a highly infectious and deadly virus. It is reported that PRRS is the most economically significant disease to affect US swine production since the eradication of classical swine fever (CSF). But EPI Air may help.

EPI Air may help PRRS infected pigs fight secondary infections. USDA-ARS tests have shown ionization to reduce pathogens in the air. Also, cleaner air leads to fewer challenges of the pigs’ respiratory systems. These two factors may help PRRS-infected pigs avoid secondary complications.

Dr. Gary Bradley, Research Center Coordinator at Murphy-Brown LLC directed trials of the EPI Technology in their nursery facilities. At a recent Pork Expo, he was asked if EPI technology could possibly reduce the movement of the PRRS Virus, Bradley only ventured, “That might be a possibility. I don’t think the negative ions could eliminate the virus from the barn. However, combined with the overhead positioning of EPI units perhaps a portable unit used at floor level could be ‘zapping’ viruses after the wash down.” He speculates there likely will be additional technology that branches off from the current EPI system. As a research scientist he’s more than willing and ready to further explore new ideas. “Preliminary results were phenomenal in our nursery units so we’re totally open to stretching our minds about a further spin off of EPI technology.”

The Canadian government also sees potential with the EPI Air and improving the productivity of hog herds while boosting the bottom line for those in the hog industry. The government of Canada, in support of the Manitoba Pork Council, is investing over $150,000 to help improve the air quality in swine barns with the EPI Air System. PRRS is reported to cost the Canadian industry an estimated $130 million per year; so using the EPI Air system to reduce and prevent the airborne transmission of PRRS is a sound investment.

EPI Air has been proven to increase average daily gain, increase average weights, and decrease mortalities. Knowing that the EPI Air makes such a significant impact on overall swine performance provides a positive outlook towards the possibilities that EPI Air also holds for PRRS.

National Environmental Winner is Minnesota pork producer

By Dick Hagen, Hagen and Associates

Being honored as a National Environmental Winner in pork production is indeed a big deal. Only four such honorees nationwide each year. And in the 18 years since the program was initiated by the National Pork Producers Council, Minnesota has claimed 12 winners.

But winning awards is the least concern of Wayne and Laura Dahl, LacQuiParle County, MN pork producers and 2012 honorees in this illustrious event. More important, much more important is presenting their 240-acre farm, hog production facilities, and neatly landscaped and artistically decorated farmstead as an entity of rural pride.

“Stewardship is a commitment that comes along with farming,” commented Wayne adding, “The public holds us accountable to be good stewards, especially in this day and age of anti-livestock activists, hidden cameras, etc. We don’t want to be just another name on that abstract. For us it is a blessing and privilege to have a farm like this. We want to leave a legacy.”

The background of Wayne and Laura dates back to 1976 when Wayne bought the farm. “I fell in love with this farm the minute I drove up the driveway 36 years ago when we were married,” says Laura referring to the country charm of the old farmstead nestled amongst a shelterbelt of aged cottonwoods and other assorted trees.

Wayne raised hogs in his Dad’s older hog sheds initially but 1979 marked the building of their first farrowing/nursery facility and a finishing setup. “I helped my Dad with his hog operation which at that time was on dirt. Even my first farrowing of our own sow herd was at my Dad’s place but now everything is produced on slats. And it has been a major transformation,” he reflected.

“You may think that pigs on dirt have all that freedom and life is good. But the actuality is that it’s much harder to control flies, rodents, mud and just the weather in general. So as we could afford it we gradually moved more of our total hog operation inside on slats. We started on partial slats in our 1979 finishing house and could see immediate benefits.

“When 2003 rolled along and we got into our major expansion, we decided to go all slats. We’ve been pleased with the comfort of the pigs, the cleanliness of the pigs, the ability to take care of individual pigs as needed and of course the much greater efficiency and ease of our daily chores also,” said Wayne.

Their expanded operation now includes a 4,400-head nursery and four 1,100-head finishing barns. Pigs are grown on contract for Mill Farm, a 5,000-sow operation owned by Greg and Paul Boerboom, Marshall, MN. The Dahls receive six groups (about 4,400 pigs per group) of 21-day-old ‘freshly weaned’ nursery pigs a year from Mill Farm. Care taker of the nursery pigs is very much the responsibility of Laura. She is well qualified.

She has a medical lab technician and also worked as a hospital physical therapy aide so getting these ‘baby’ pigs off to a good start is her special challenge. “I love it,” she said. “These little rascals are always fun to watch. I carefully note their weights. Every batch has a few tail-enders so I sort them into their own pen and even provide a special mat, about 4’ x 6’, that I place over the slats close by their tube feeders. Three times a day I put some of the same starter ration on this mat so if they’re not yet ready to nibble at the tube feeders they can feed off this mat.”

She sorts and groups by size and makes certain they find the nipple waterers. Pigs in that ‘hospital pen’ get even closer attention. “I look at every pig, from snout to tail, every day. Treat your pigs well and they treat us well,” noted Laura. At 40 to 60 lbs, pigs move to finishing barns. Marketing is at about 280 lbs.

Technology gets noted

Anez Consulting Inc., Willmar, MN assists with nutrient management, crop scouting and the implementation of conservation practices on the farm. Manure from the 8’ deep pits is tested with application rates calibrated to meet the fertilizer needs for the next year’s crop. A 10,000-gal. tanker equipped with a flow meter applies the manure with GPS precision in soybean stubble.

The Dahls use a manure additive to help stabilize the nitrogen in the fall-applied manure. Also the feed additive, phytase, is used to reduce the amount of phosphorous in the manure. This enables them to boost manure application rates by up to 20% without building phosphorous in the soil.

Nothing gets ignored in a modern swine operation. Pig comfort is first and foremost in their operation. And that includes the adaption of a few ‘technological wrinkles’ still unfolding in much of the swine industry. But Wayne doesn’t mind being at the front end of new technologies. “He’s a technology nerd,” chuckled Laura. Wayne agreed, “Yes, we’ve come a long way in pork production and we’re always looking for new ideas that might help us to do a better job.”

Indeed. Like he was one of the first in the nation to install EPI technology. Designed by Baumgartner Environics, Olivia, MN the EPI (electrostatic particulate ionization) Air System discharges literally millions of negatively charged ions into the air space every second. These negative ions attract dust particles polarizing them to act like magnets and fastening to whatever surface they touch first.

“Yes, we are seeing lower dust levels and that’s appreciated by the pigs and the workers in the buildings. It also means fewer odor-carrying dust particles in the ventilation system,” noted Wayne. That lack of ‘hog barn’ odor is very noticeable to visitors.

Water conservation too

Water meters are also part of technology at their farm. “Being aware of water quality is a starting point in conservation farming, even as it pertains to your livestock. With these meters we are constantly monitoring our water. So if we notice any slowdown in pig performance we check the meters to see if there has been a drop off in water consumption. If that happens that’s a good indication of needing to take a closer look at the animals,” said Wayne.

A new tool for better water consumption is what’s called a fresh water trough. Yes, nipples are the traditional water source for most swine operations including the Dahls but they’ve added something new in their nursery. “What we have here is a water pan at floor level with water level controlled by a bladder that maintains constant water level. When you get 12 to 13-lb, 3-week old pigs newly weaned from their mothers, the first thing they want is a drink of water. But these metal nipple waters are totally new to them however they can see water in these pans and very quickly are drinking from them. Plus we’re told these pans reduce water wastage 20 to 30%. We’ve really seen an improvement.”

They’ve also switched from using chloride in their watering system to hydrogen peroxide. Using a product called Oxy Blast for treating nursery water, Wayne indicated it also reduces manure pit odors because the oxygenated water that drips from the nipple waterers produces an anaerobic environment in the pit below the slatted floors.

Also new is a simple in-line structured water filter device only about 12-inches long and as Wayne describes, “It’s just glass marbles that water passes through and the claim is that this process energizes the water which in turn means better water utilization within the pigs system.”

Cautious about claiming ‘scientific results’, Wayne simply stated. “Between the Oxy Blast system and this structured water we’re seeing our young pigs get off to a much better start.” He pointed out however there are so many variables in each group of pigs that it’s difficult to pin-point the success.

Their system revolves around 9 weeks for isoweans in the nursery facility and 18 weeks in the finishing barns. After each 9-week nursery timeframe, the entire structure gets a pressure washed, hot-water cleaning “….so it pretty much looks and smells like the inside of a car wash.” The same process happens after each cleanout of the finishing barns.

A farm for all ages

Wayne says the sparkly clean appearance of their hog operation is now typical industry wide of America’s pork producers. But it’s not all high-tech that drives the Dahl’s’ environmental stewardship. Much goes to simple things like keeping their farmstead comfortably clean and tremendously fun for their own grandchildren, neighboring kids, even classes from the local schools for a look at Laura’s incredible ‘petting zoo’ which includes an incredible variety of unique birds, chickens, pheasants, goats, geese, rabbits and a pair of adorable llamas.

“I’ve always loved animals. I remember as a little girl being so sensitive about my little pets. It’s my nature. I was born with it apparently. My pets are good therapy for me, for my friends, and especially for little children. My grandmother used to love her chickens. I grew to cherish her love for chickens. I even decorate my kitchen with chicken art work,” says this lady with an inexhaustible heart of love and sharing. “Grandparents love to bring their little grandchildren to our house,” she noted.

Wayne and his brother David team up to grow 1,800 acres of crops in a corn-soybean rotation. The Dahl’s youngest son Jordan who is also a professional wood carver is an integral farming partner. Also a neighboring young farmer, Tanner Winge, is a part-time assistant on the swine enterprise. “He’s just an exceptional young guy. I can’t say enough about his animal husbandry skills,” said Wayne.

Their family includes Tanya, age 34; Tera, 31; Terese Viessman, 29, with husband Nate and children Skylar, Walker and Tucker; Jarrett, 27 and Jordan, 25. Both sons have become skilled chain saw sculpturing talents with Jarrett winning 1st place in the 2012 Alaska Chain Saw Carving show.

About the National Environmental Steward Award

The National Pork Checkoff, along with its cosponsor, National Hog Farmer magazine, selected four pork farms to be honored as the 2012 National Pork Environmental Stewards. This year’s award recipients are: Dahl Family Farm, Dawson, MN; Future View Farm, Willow Street, PA; Trail’s End Sow Farm, Ames, Ok; Reed Family Farms, Ottumwa, IA.

The Environmental Steward award winners were selected by a panel represented by other hog farmers and environmental organizations. The committee reviewed applications from pork producers who are committed to upholding the ideal relationship between pork production and the environment. The applicants’ farms were evaluated on their manure management systems, water and soil conservation practices, odor-control strategies, farm aesthetics and neighbor relations, wildlife habitat promotion, innovative ideas used to protect the environment and an essay on environmental stewardship.

Minnesota honorees over the years are the following: 2012, Wayne and Laura Dahl of Dawson; 2009,Brandon and Monica Schafer, Schafer Farms, Goodhue; 2008,Jim and JoAnn Veldkamp,Veldkamp Farms, Jasper; 2007,Mike Haupert of M & J Farms, Hadley; 2006, David, Brian and Bob Braun of Braun Farms, Le Sueur; 2005,Sandy and Ben Ludeman of Saratoga Pork, Tracy; 2004,Dan and Midge Boettger of Three Generation Pork, New Richland; 2003, Dr. Dick Nicolai and Sam Watkins of Nicolai Pork Producers, Inc., Hector; 2000,Scott and Shelley Schwartz of Schwartz Farms, Garvin; 1998, Peter and Paul Zimmerman, and Cliff Jes of Woodville Pork, Waseca; 1996, Don Lafferty of Tru-Joy Farms, New York Mills; 1995,Marlin and Wilda Pankratz of Mountain Lake.

A Breath of Fresh Air

Recently, Brandi Buzzard, an Agricultural Communicator, Writer, and Scientist who works at Kansas State University, wrote about EPI Air Technology on SwineWeb.com in an article titled “Airing it Out”. At the Animal Science and Industry Department at Kansas State University some of her responsibilities were to coordinate and conduct research trials aimed at developing low stress production practices for swine and cattle producers. Brandi noted, “While I generally enjoy conducting research in swine barns, I must admit that I don’t enjoy what I unaffectionally call ‘hog barn crud’ or the hacking and coughing I experience for the next 2 days after being in the barns.”

What Brandi experienced is the same poor air quality in the barns that swine, poultry or other livestock livein each day. The employees that work in the enclosed swine facilities breathe in the excessive particulate matter in the air, which also contains high levels of ammonia. Needless to say, the dust, gases, and ammonia can be a concern to animals and humans alike. Brandi feels that EPI Air has great possibilities, “ I think it has huge potential to increase herd respiratory health as well as improve the working environment for employees.”

Another student at K-State Swine unit is currently conducting a study to evaluate the effectiveness of the EPI Air system. Although the study is still going on and the results are not available yet, it looks like a promising solution for swine producers. Brandi is excited to hear the results. She explains, “Well, for starters the amount of dust that is removed from the air is astounding. Seeing all that particulate matter stacked on inanimate objects like fences and the walls really opens your eyes to how much dust is flying around in the air and being ingested by both the employees and the animals. If they’re concerned at all about respiratory health for either, they’ll want to consider EPI.”

Brandi is passionate about agriculture and it shows. She writes about it on her blog and on Twitter. Agriculture employs both her family and her husband’s family, and as Brandi says, “It’s our way of life and all we’ve ever known.” Brandi’s philosophy is “I write and speak out and tell my story – if I can help one more person learn about agriculture, then I’ve done my job.”

Technology to the Rescue

By Dick Hagen, Hagen and Associates

Livestock producers are fully aware of the ‘big pain’ building in their cost accounting ledger. Feed prices, especially corn, keep escalating. On August 2, Chicago Board of Trade had September 12 futures for corn hovering around $8; September soybeans at $16.35. Chicago Mercantile meat futures were trading at $76.85 for October 12 hogs; cattle at $140.12.

The dilemma? Processors can’t ramp up prices enough to offset increasing production costs of producers without significant resistance from consumers. In essence, increasing meat prices at the retail counter inevitably generates shrinking sales. Rationing is setting in at all levels of the food chain, including pork producers.

Unfortunately no one has the ‘inside intelligence’ to predict how long the belt tightening will last, nor how severe the pain will become. So how do you survive the current squeeze, especially when it continues with such hour-by-hour volatility? Well, after you have answered the question: “How many of my barns will continue to have pigs in them?”, you need to reduce mortalities and improve feed efficiency.

EPI Air to the rescue? Murphy-Brown, LLC thinks so. Their results were solid. They tested EPI technology on 44,000 nursery pigs. Check these rather remarkable results:

- Average daily gain increased 12.2%

- Average weights increased by 9.3%

- Mortalities were reduced by 26.1%

Workers in these Murphy-Brown facilities also appreciate the ‘cleaner air’ environment.

Here’s why: The EPI barns had a 55% reduction in ammonia versus the control barns; a 58.6% reduction in hydrogen sulfide.

Comments John Baumgartner, BEI President, “My question to pork producers is simply this: Is an investment that returns your money within 18 months a good investment? Murphy-Brown estimated their payback at half of that, 9 months. And that was before the drought. In today’s ‘crunch time’ economy with increased feed costs, those return-on-investment (ROI) calculations are even faster.”

Proof of the cost-effectiveness of EPI technology is Murphy-Brown going ‘system wide’ throughout their entire Western Division with EPI units. We’re talking 655,000 nursery spaces plus 864,000 wean-to-finish spaces.

Said Dr. Steve Pollmann, President, Murphy-Brown Western Division, “This is a significant step change in environmental systems. We’re excited. The science is sound. The take away is that EPI in our test runs provided documented evidence of the potential benefit of this technology.”

Sums up Baumgartner, “We think EPI technology is on the threshold of becoming ‘must have’ technology. Especially during these difficult times, improved performance is the key to sustainability and a quick ROI has always made business sense.”

Interested in learning more about EPI technology? Contact us at 800-823-4234 or follow @EPIAir on Twitter.

Why Use EPI?

Leaders in the livestock industry are continually looking for ways to improve the performance of their livestock. Just like food and water, clean air is essential to an animal’s health. Improving in-barn air quality is now achievable with EPI Air Technology by Baumgartner Environics.

Here are some reasons to use EPI to improve air quality:

Improve Production

Nurseries who have used EPI Air have noted significant production gains. For instance, Murphy-Brown cited an increase of ADG by 12.2%, and an increase in weights of 9.3%.

Reduce Mortalities

Cleaner in-barn air quality leads to a reduction in livestock mortalities. Murphy-Brown reported a reduced mortality rate an astonishing 26.1%.

Reduce Barn Emissions

In-barn emissions are reduced in barns that use EPI Air. When Murphy-Brown tested the air quality in barns with EPI installed, compared to the control barns, there was a significant reduction in particulate matter, ammonia, hydrogen sulfide, and odor.

34 Week Return on Investment

On top of the environmental reasons to use this dust reduction system, EPI also makes economical sense. Murphy-Brown reported a quick, 34 week ROI with the EPI Air System, making it a must-have technology in their hog barns system-wide.

With results such as improved production, reduced mortalities, and reduced barn emissions, it is easy to see why improving in-barn air quality with EPI Air improves the overall performance of your livestock in a cost-effective way.

To learn more about EPI Air and all of its benefits, please watch this video or contact us.

How to Clean a Barn with EPI Installed

Often we hear questions from customers regarding how to clean a barn that has the EPI Air® System installed. The answer is basically “Clean the barn like usual,” but here are a few things to remember.

Think Differently about Dust

The EPI Air® System requires a bit of a paradigm shift regarding room cleanliness, since a thick layer of visible dust will collect on surfaces in the barn. It is important to remember that dust collected on surfaces is superior to dust suspended in the breathable air. Even though the dust will be more noticeable on these surfaces, removing dust from the air enhances ventilation and data shows that it improves production.

The EPI Air® System requires a bit of a paradigm shift regarding room cleanliness, since a thick layer of visible dust will collect on surfaces in the barn. It is important to remember that dust collected on surfaces is superior to dust suspended in the breathable air. Even though the dust will be more noticeable on these surfaces, removing dust from the air enhances ventilation and data shows that it improves production.

Clean the Barn like Usual

When the animal production phase has been completed, the room can be cleaned as part of normal barn washing operations. The EPI Air® components can be power-washed when the system is powered off. A handheld leaf blower also works well to remove the collected dust from the surfaces to get them out of the barn. Turn the fans on to purge and blow the dust off barn surfaces. Dust is also removed easily by sweeping with a broom or rapping on the surfaces with a rubber mallet.

What other questions do you have about cleaning a barn with the EPI® System installed?

8 Ways to Take a Breath of Fresh Air this Earth Day

This Earth Day, there are many ways that you can show your respect for the Earth. From planting a tree, to cleaning the ditches, or starting a new routine in your home or business that will help your reduce, reuse, or recycle. Every green effort counts to help the earth and its resourceful land, water and air.

At Baumgartner Environics, we are taking the importance of indoor air quality one step further, because not only is breathing clean air vital for human beings, but animals as well. The EPI Air System helps the livestock industry improve their in-barn air quality through dust reduction at the source. Our hypothesis is that cleaner air in livestock barns leads to improvement in animal growth and livability.

8 More Ways to Improve your Indoor Air Quality:

- Avoid second-hand smoke, and don’t smoke yourself.

- Get some houseplants! We all know that plants convert carbon dioxide into oxygen through photosynthesis, but a NASA/ALCA study also showed that many houseplants also remove harmful elements such as trichloroethylene, benzene, and formaldehyde from the air.

Install a carbon monoxide detector to make sure your home stays free of this deadly gas. Also be sure to never let your car run while parked in the garage.

Install a carbon monoxide detector to make sure your home stays free of this deadly gas. Also be sure to never let your car run while parked in the garage.- Check your home for radon. Radon is the second leading cause of lung cancer and is odorless and colorless. Tests can be purchased from the hardware store or requested from the EPA.

- Change the filters in your air conditioner and furnace before the heating and cooling seasons begin.

- Avoid using chemicals when you can. For instance, get no or low -VOC paints and non-toxic home cleaners and air fresheners. Try soy candles or homemade cleaners to keep it natural.

- Keep an eye out for visible molds in your home that could be dangerous and an indicator of moisture and bacteria problems.

- Open the windows, better yet – go outside! Fresh air does wonders for the body and to clear your mind.

This Earth Day, think about how you can make extra efforts to help the earth. Could you ride-share to reduce your carbon footprint? There are many ways that you can reduce air pollution, and every bit counts.

How are you celebrating Earth Day? What extra efforts are you taking to help keep the earth’s land, water, or air clear of pollutants?

Murphy-Brown talks to National Hog Farmer about Clean Air

In the September 19, 2011 issue of National Hog Farmer, writer Dick Hagen addressed the new buzzwords in the swine industry – Electrostatic Particle Ionization (also known as EPI). Read the excerpts below from the article “Help Clear the Air in Hog Barns”.

EPI Air Technology has met and surpassed the criteria laid out by Murphy-Brown, LLC, the world’s largest pork producer. Murphy-Brown, LLC installed EPI units in two, 2,000-head production nurseries.

Bob Coffelt, Business Development Manager, and Steve Pollmann, President of Murphy-Brown’s Western Division shared their experience with EPI. Here is what they had to say.

“The strength of the probability out of our testing convinced us fairly quickly that this appears to be an innovation well worth our time,” notes Bob Coffelt, business development manager at Murphy-Brown’s western division. “When we first looked at it, the system appeared to be fairly unorthodox. But the results speak for the system. Pigs simply do better,” Coffelt says.

“Maintenance requirements are low and the installation unobtrusive,” he adds. “It tends to challenge one’s concept of the improbable values of dust suspension and odor issues. The sensory impact would lead one to believe that odors were lower in rooms equipped with EPI.”

“This is a significant change in environmental systems with a net result of improved pig performance,” explains Steve Pollmann, president of Murphy-Brown’s western division. “We’re excited. The science is sound. Even though understanding the technology is a bit of a challenge, the takeaway is that EPI in our test runs provided documented evidence of the potential benefit of this technology.”

However, the only logical means of getting real mileage out of EPI technology depended upon conclusive evidence from the swine world. Murphy-Brown was receptive to testing the technology and its impact on pig health and gains in production. Click here to view the detailed results and data from the Murphy-Brown installations of EPI.

Read the complete article “Help Clear the Air in Hog Barns” in National Hog Farmer.

Read other articles where EPI Air is featured in the News.