It’s called electrostatic particle ionization and an Olivia, Minn., company says the technology can help confinement livestock producers be more efficient.

As published in AgWeek. Monday, March 18, 2018

It’s called electrostatic particle ionization and an Olivia, Minn., company says the technology can help confinement livestock producers be more efficient.

Put simply, EPI “scrubs the air” to create healthier air for pigs to breathe, says John Baumgartner, president of Baumgartner Environics.

His company manufactures and sells EPI Air, a patented dust reduction system that generates electrically charged ions, which clear the air of dust and other harmful emissions such as ammonia and hydrogen sulfide.

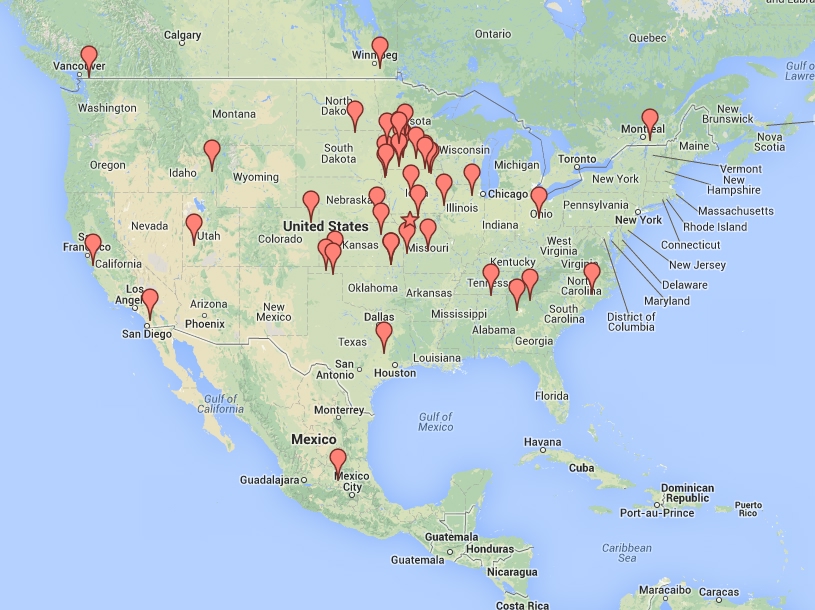

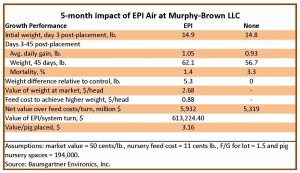

The system recently received high marks from Murphy-Brown LLC, the world’s largest pork producer. Murphy-Brown used the technology at its commercial nurseries in Milford, Utah. The project, which involved 600,000 pigs in what EPI Air calls a “system-wide commercial performance,” not merely a test, found that the system reduced swine mortality and increased daily weight gains at the Utah plants.

“Yes, we are indeed pleased; 600,000 pigs don’t lie,” Bob Coffelt, Murphy-Brown’s business development directors, says in a news release.

His company plans to install the technology in all its grower and finishing facilities, Coffelt says in the release.

David Newman, North Dakota State University Extension Service swine specialist, says he’s heard of the EPI technology and the Murphy-Brown tests, but isn’t familiar with the details.

Nonetheless, the basic concept appears sound, he says.

“It’s about reducing dust and improving air quality. We know that if you can improve air quality, you’ll improve efficiency in your pigs. That’s been scientifically proven,” Newman says.

USDA roots

The Olivia company’s product builds on research conducted by the U.S. Department of Agriculture’s Agricultural Research Service in Athens, Ga., Baumgartner says.

Baumgartner Environics licensed an ARS patent for the technology to use in agriculture. The company further developed the technology, making improvements and taking costs out of the system.

The Olivia company has submitted several patents of its own to reflect improvements it’s made, he says.

EPI Air is a modular system. One power supply for the system can treat about 15,000 square feet, at a cost approaching $1.70 per square foot, Baumgartner says.

The system installed at the Murphy-Brown facilities in Utah paid for itself in just 75 days, according to Baumgartner Environics.

The cost of operating the system is roughly the same as the cost of running a 100-watt light bulb, Baumgartner says.

No special outlet or wiring is needed, he says.

‘Healthy skepticism’

Baumgartner started Baumgartner Environics in 1989 as an environmental consulting company.

Later, it became an environmental products company, focusing on providing systems to agriculture that address environmental issues and contribute to profitability.

Baumgartner Environics’ next product is EPA Air II. Billed as an improved version of the original technology, it will be released in April. The next version will, among other things, concentrate on providing cleaner air in the “pig breathing zone,” according to the company.

Some people have what Baumgartner calls “general healthy skepticism” to the product.

“The commercial data is so good that most people find it hard to believe. That causes skepticism. You can’t see these ions. It’s like ‘How can this possibly work? It doesn’t cost much to operate. How can this work?’” he says.

In time though, “It’s going to become understood that this is a technology everyone producing confinement livestock in the future will adopt in their operation,” Baumgartner says.

“I think it’s game-changing technology,” he says.